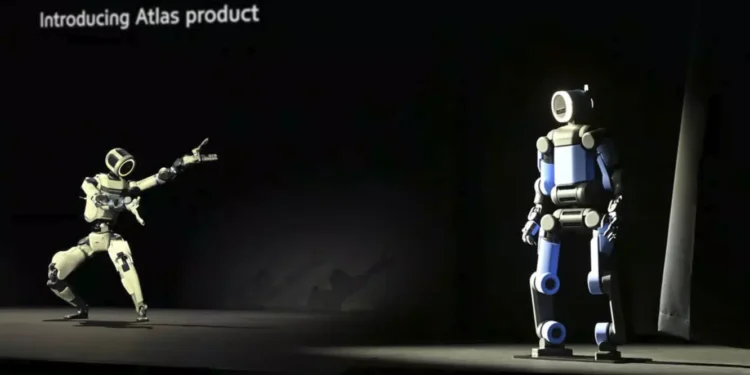

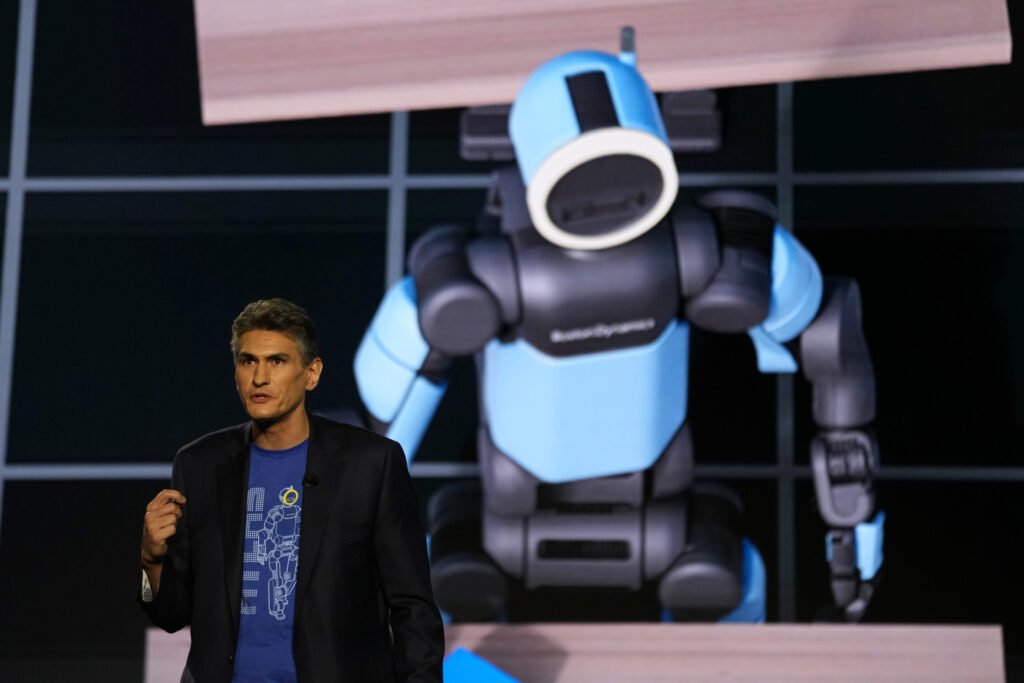

CES 2026, held in Las Vegas, was an event that showcased many new innovations in various categories, including electric vehicles, Artificial Intelligence (AI), and Augmented Reality (AR), but one product stood out—the new Atlas humanoid robot created by the partnership between Hyundai and Boston Dynamics.

Atlas will enable Hyundai to create realistic mobility for robots in real-world industries as well as represent a major step toward a future of smart, mobile, and collaborative robots.

What Is Atlas Robot?

Created initially through collaboration with Boston Dynamics and now advanced through Hyundai Motor Group’s vision, Atlas is a bipedal humanoid robot designed to mimic the dexterity, balance, and agility of a human being—and in many cases, to surpass it.

Atlas is an electric-powered robotic humanoid with an approximate height of 1.5 m and weight of approximately 90 kg. The Atlas robot uses an electric motor system for its actuation system compared to the use of hydraulic systems that was previously the norm for bipedal robotics.

Through the elimination of hydraulic systems with Atlas, the new autonomous robot system will enable more efficient operations and greater precision due to its ability to operate within its programmable & automated motion patterns. The CES 2026 reveal of the new look of the Atlas droid demonstrated a new, more streamlined form as well as increased modularity, leading to the ability to produce parts more easily.

Functions and Capabilities

Hyundai did not just demonstrate a walking multi-purpose robot but demonstrated a very versatile machine that can do a very complex and real-world task. Below is a summary of some of the main capabilities of Atlas as demonstrated at CES:

1. Dynamic Mobility

Atlas is extremely agile when it walks, runs, and sidesteps and turns. Its joints provide for a full range of motion, allowing Atlas to go from standing to crouching and back to reaching.

- Walking speed: ~5 km/h

- Jump and recovery balance: Can stabilize itself even when pushed or bumped

- Terrain adaptation: Adjusts steps dynamically on uneven or inclined surfaces

2. Object Manipulation

The latest version of Atlas has the benefit of highly articulated, precision hands and AI vision, allowing it to identify, pick up, carry, and move both simple and complex items, regardless of their weight or other aspects.

- Payload capacity: Up to 30–35 kg

- Grip adaptability: Can handle both delicate components (like tools or cables) and heavy materials

- Multi-object sequencing: Demonstrated picking, stacking, and organizing components autonomously

3. Perception and Awareness

Atlas uses a fusion of 3D LiDAR, stereo cameras, and tactile sensors to perceive its environment in real time.

- 360° situational mapping for obstacle avoidance

- Human recognition to identify and safely coordinate with nearby workers

- Autonomous task planning through AI learning models that adapt to new surroundings

4. Balance and Stability

One of Atlas’s greatest strengths is its ability to maintain balance through a bio-inspired balance system that adjusts its posture through small adjustments to its joints and actuators. The robot has:

- Dynamic stability control mimics human reflexes

- Can recover from slips, low impacts, or load imbalances

5. Energy and Efficiency

Unlike most robots that are powered by hydraulic systems, Atlas is powered by a battery. It has the following features:

- Up to 2 hours of operation per charge (depending on workload)

- Fast-swap battery module for continuous industrial use

- Regenerative motion system that recycles kinetic energy into stored power

Live Demonstration at CES 2026

A demonstration of real-time logistics from Hyundai, during its CES presentation, showcased Atlas’ abilities: picking up pieces from a storage rack, transporting them across the stage, and then correctly positioning them. People were surprised not only by how well Atlas executed these tasks but also by the natural, flowing manner in which Atlas moved and made decisions based on AI guidance.

Earlier versions of Atlas were primarily developed as research tools, serving as test platforms for robotics innovation. The current version, however, is purpose-built for industrial use and has already proven its ability to operate effectively in real-world manufacturing environments. According to Hyundai engineers, Atlas’s advanced software enables it to learn autonomously through continuous data feedback and reinforcement learning—allowing the robot to refine its performance and adapt to new tasks over time.

From Prototype to Production

Hyundai said that by 2028, Atlas will be set to deploy on the factory floor. Initial applications of Atlas involve support for an assembly line where it will assist in handling a variety of materials, conducting inspections of parts and products for quality assurance, and performing numerous repetitive manual tasks.

Atlas will hopefully be utilized across a number of industries, including construction, logistics, disaster relief, and the healthcare industry.

According to Hyundai, there will be a mix of human workers doing creative and supervisory jobs, and robots like Atlas taking care of heavy enough to not just be able to do the work but do the most dangerously challenging sections of those new types of work.

Why Atlas Matters

The debut of Atlas at CES 2026 represents more than a technological milestone; it’s a symbol of human-robot collaboration entering a practical age.

As Hyundai continues integrating robotics with AI, mobility, and manufacturing, Atlas stands as a powerful example of how robotics can:

- Increase workplace safety and productivity

- Address global labor shortages

- Push forward the frontier of autonomous systems

The Atlas prototype’s debut marks the dawn of an era where robots are no longer just tools—they’re partners.